©Endress+Hauser

Yeni seri

The specialist for life sciences with an ultra-compact transmitter

Ayrıntılı bilgi

Specialist for life sciences with a compact, easily accessible transmitter

Ayrıntılı bilgi

Specialist for life sciences, as remote version with up to 4 I/Os

Ayrıntılı bilgi

Basit ürünler

Seçmesi, kurması ve çalıştırması kolay

Teknik mükemmellik

Sadelik

Standart ürünler

Güvenilir, sağlam ve az bakım gerektiren

Teknik mükemmellik

Sadelik

Üst düzey ürünler

Son derece fonksiyonel ve uygun

Teknik mükemmellik

Sadelik

Özelleştirilmiş ürünler

Zorlu uygulamalar için tasarlanmış

Teknik mükemmellik

Sadelik

FLEX seçimleri

Teknik mükemmellik

Sadelik

Fundamental seçim

Temel ölçüm ihtiyaçlarınızı karşılayın

Teknik mükemmellik

Sadelik

Lean seçim

Ana proseslerinizin üstesinden kolayca gelin

Teknik mükemmellik

Sadelik

Extended seçim

Proseslerinizi yenilikçi teknolojilerle optimize edin

Teknik mükemmellik

Sadelik

Xpert seçim

En zorlu uygulamalarınızda uzmanlaşın

Teknik mükemmellik

Sadelik

Product headline

The specialist for life sciences with extended transmitter functionality. Dedicated for applications under sterile conditions in the life sciences industry.

Sensor features

Highest process quality – fully compliant to industry requirements. Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in/outlet run needs. ASME BPE, 3-A and EHEDG conform & low delta ferrite. Electropolished measuring tube in 1.4435 (316L).

Transmitter features

Quality – software for filling & dosing, density & concentration, advanced diagnostics. Flexible data transfer options – numerous communication types. Automatic recovery of data for servicing. 4‐line backlit display with touch control. Device in compact or remote version.

Wetted materials

Measuring tube: 1.4435 (316L)

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density, concentration

Max. measurement error

Mass flow (liquid): ±0.1 %

Measuring range

0 to 70 000 kg/h (0 to 2570 lb/min)

Medium temperature range

–50 to +200 °C (–58 to +392 °F)

Ambient temperature range

Standard: –20 to +60 °C (–4 to +140 °F)

Sensor housing material

1.4301 (304), corrosion resistant

Transmitter housing material

Powder‐coated die‐cast aluminium

Degree of protection

IP67, type 4X enclosure. Remote transmitter: IP67, type 4X enclosure

Display/Operation

4‐line backlit display with touch control (operation from outside)

Outputs

4 modular outputs:

Inputs

2 modular inputs:

Digital communication

HART, PROFIBUS PA/DP, FOUNDATION Fieldbus, Modbus

Power supply

DC 16 to 62 V

Hazardous area approvals

ATEX, IECEx, FM, CSA, NEPSI

Other approvals and certificates

3.1 material, calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR, SIL

Functional safety

Functional safety according to IEC 61508, applicable in safety-relevant applications in accordance with IEC 61511

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR

Pressure approvals and certificates

Hygienic approvals and certificates

Product headline

The specialist for life sciences with extended transmitter functionality. Dedicated for applications under sterile conditions in the life sciences industry.

Sensor features

Highest process quality – fully compliant to industry requirements. Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in/outlet run needs. ASME BPE and 3-A conform & low delta ferrite. Electropolished measuring tube in 1.4435 (316L).

Transmitter features

Quality – software for filling & dosing, density & concentration, advanced diagnostics. Flexible data transfer options – numerous communication types. Automatic recovery of data for servicing. 4‐line backlit display with touch control. Device in compact or remote version.

Wetted materials

Measuring tube: 1.4435 (316L)

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density, concentration

Max. measurement error

Mass flow (liquid): ±0.1 %

Measuring range

0 to 70 000 kg/h (0 to 2570 lb/min)

Medium temperature range

–50 to +200 °C (–58 to +392 °F)

Ambient temperature range

Standard: –20 to +60 °C (–4 to +140 °F)

Sensor housing material

1.4301 (304), corrosion resistant

Transmitter housing material

Powder‐coated die‐cast aluminium

Degree of protection

IP67, type 4X enclosure. Remote transmitter: IP67, type 4X enclosure

Display/Operation

4‐line backlit display with touch control (operation from outside)

Outputs

4 modular outputs:

Inputs

2 modular inputs:

Digital communication

HART, PROFIBUS PA/DP, FOUNDATION Fieldbus, Modbus

Power supply

DC 16 to 62 V

Hazardous area approvals

ATEX, IECEx, FM, CSA, NEPSI

Other approvals and certificates

3.1 material, calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR, SIL

Functional safety

Functional safety according to IEC 61508, applicable in safety-relevant applications in accordance with IEC 61511

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR

Pressure approvals and certificates

Hygienic approvals and certificates

Characteristic / Application

Coriolis mass flowmeter complying with ASME BPE, ISPE, FDA, 3-A

Process temperature

-50...+200°C

Process pressure

PN 16...40

Output

4...20mA

Certificates / Approvals

ATEX

Product headline

The specialist for life sciences with extended transmitter functionality. Dedicated for applications under sterile conditions in the life sciences industry.

Sensor features

Highest process quality – fully compliant to industry requirements. Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in/outlet run needs. ASME BPE, 3-A and EHEDG conform & low delta ferrite. Electropolished measuring tube in 1.4435 (316L).

Transmitter features

Quality – software for filling & dosing, density & concentration, advanced diagnostics. Flexible data transfer options – numerous communication types. Automatic recovery of data for servicing. 4‐line backlit display with touch control. Device in compact or remote version.

Wetted materials

Measuring tube: 1.4435 (316L)

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density, concentration

Max. measurement error

Mass flow (liquid): ±0.1 %

Measuring range

0 to 70 000 kg/h (0 to 2570 lb/min)

Medium temperature range

–50 to +200 °C (–58 to +392 °F)

Ambient temperature range

Standard: –20 to +60 °C (–4 to +140 °F)

Sensor housing material

1.4301 (304), corrosion resistant

Transmitter housing material

Powder‐coated die‐cast aluminium

Degree of protection

IP67, type 4X enclosure. Remote transmitter: IP67, type 4X enclosure

Display/Operation

4‐line backlit display with touch control (operation from outside)

Outputs

4 modular outputs:

Inputs

2 modular inputs:

Digital communication

HART, PROFIBUS PA/DP, FOUNDATION Fieldbus, Modbus

Power supply

DC 16 to 62 V

Hazardous area approvals

ATEX, IECEx, FM, CSA, NEPSI

Functional safety

Functional safety according to IEC 61508, applicable in safety-relevant applications in accordance with IEC 61511

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR

Pressure approvals and certificates

Hygienic approvals and certificates

151 dokümanları

Proline Promass 80P, 83P

Technical Information

The specialist for life sciences with extended transmitter functionality

EN

TR

Almanca French İtalyanca Japonca Lehçe Çince

01/04/2015

15/12/2010

05/11/2010

25/01/2010

09/07/2009

Dil:

İngilizce

Versiyon:

01/04/2015

Dosya boyutu:

1.4 MB

Dosya adı:

TI00078DEN_1415.pdf

Proline Promass 83

FOUNDATION Fieldbus

Operating Instructions

Coriolis Mass Flow Measuring System (with FOUNDATION Fieldbus

EN

TR

Almanca Japonca

15/10/2012

01/10/2011

08/06/2010

01/10/2009

01/11/2008

Dil:

İngilizce

Versiyon:

15/10/2012

Dosya boyutu:

2 MB

Dosya adı:

BA00065DEN_1412.pdf

Proline Promass 83

FOUNDATION Fieldbus

Device

Functions

Description of the device functions (0ptions and inputs). Additional

EN

TR

Almanca Japonca

01/11/2008

01/12/2006

01/12/2005

01/12/2000

Dil:

İngilizce

Versiyon:

01/11/2008

Dosya boyutu:

1.5 MB

Dosya adı:

BA066DEN_1108.pdf

Proline Promass 83

PROFIBUS DP/PA

Description of

Device Functions

Description of the device functions (0ptions and inputs). Additional

EN

TR

Çekçe Almanca İtalyanca

01/11/2008

01/01/2006

01/03/2005

01/06/2001

Dil:

İngilizce

Versiyon:

01/11/2008

Dosya boyutu:

1.9 MB

Dosya adı:

BA064DEN_1108.pdf

Proline Promass 83

HART

Operating Instructions

Coriolis flowmeter

EN

TR

Bulgarca Çekçe Almanca İspanyolca French Macarca İtalyanca Japonca Lehçe Portekizce Rusça Çince

01/12/2014

15/10/2012

01/10/2011

01/03/2010

01/10/2008

Dil:

İngilizce

Versiyon:

01/12/2014

Dosya boyutu:

2.3 MB

Dosya adı:

BA00059DEN_1514.pdf

Proline Promass 83

HART

Description of Device Functions

Coriolis flowmeter

EN

TR

Bulgarca Çekçe Almanca İspanyolca French İtalyanca Japonca Lehçe Portekizce Rusça

01/12/2014

01/09/2008

01/12/2005

01/11/2004

15/10/2003

Dil:

İngilizce

Versiyon:

01/12/2014

Dosya boyutu:

1.3 MB

Dosya adı:

BA00060DEN_1314.pdf

Proline Promass 83

PROFIBUS DP/PA

Operating Instructions

Coriolis Mass Flow Measuring System (with PROFIBUS DP/PA interface)

EN

TR

Çekçe Almanca İtalyanca Rusça

15/10/2012

01/10/2011

08/06/2010

01/11/2008

01/08/2007

Dil:

İngilizce

Versiyon:

15/10/2012

Dosya boyutu:

3.6 MB

Dosya adı:

BA00063DEN_1412.pdf

Proline Promass 83

Modbus RS485

Operating Instructions

Coriolis Mass Flow Measuring System (with Modbus RS485

EN

TR

Almanca Rusça

15/10/2012

01/10/2011

08/06/2010

01/11/2008

01/12/2006

Dil:

İngilizce

Versiyon:

15/10/2012

Dosya boyutu:

2.5 MB

Dosya adı:

BA00107DEN_1412.pdf

Proline Promass 83

MODBUS RS485

Description of

Device Functions

Descriptions of the device functions (Options and In-/Outputs)

EN

TR

Almanca

01/11/2008

01/12/2005

01/11/2004

Dil:

İngilizce

Versiyon:

01/11/2008

Dosya boyutu:

1.8 MB

Dosya adı:

BA108DEN_1108.pdf

Proline Promass 83

Brief Operating Instructions

Coriolis flowmeter

EN

TR

Almanca İspanyolca Fince French İtalyanca Portekizce Rusça Çince

26/05/2016

06/08/2015

15/10/2012

01/10/2011

01/03/2011

Dil:

İngilizce

Versiyon:

26/05/2016

Dosya boyutu:

2 MB

Dosya adı:

KA00024DEN_1716.pdf

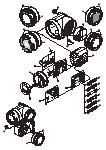

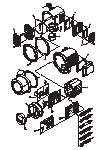

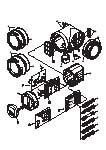

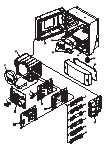

Çizimde yedek parçaları numaraya göre ara

60 spare parts & accessories

60 spare parts & accessories

60 spare parts & accessories

Kit power s.b. 40/8X/65 220V REx000

Çizim numarası

Sipariş kodu

F

50098557

Kit p.s.b.40/8X 220V REx000 HE

Çizim numarası

Sipariş kodu

F

71039431

Kit p.s.b.40/8X 220V REx000 HE

Çizim numarası

Sipariş kodu

F

71039431

Kit power s.b. 40/8X/65 220V REx120 Ex

Çizim numarası

Sipariş kodu

F

50098558

Kit p.s.b.8X 220V REx120 HE Ex

Çizim numarası

Sipariş kodu

F

71039432

Kit p.s.b. 40/8X 220V REx330 Ex

Çizim numarası

Sipariş kodu

F

71097758

Kit p.s.b.8X 220V REx330 HE Ex

Çizim numarası

Sipariş kodu

F

71097760

Kit P.s.b. 40/8X/65 24V REx000

Çizim numarası

Sipariş kodu

F

50098565

Kit p.s.b.8X 24V REx000 HE

Çizim numarası

Sipariş kodu

F

71039434

Kit P.s.b. 40/8X/65 24V REx120 Ex

Çizim numarası

Sipariş kodu

F

50098566

Kit P.s.b. 8X 24V REx120 HE Ex

Çizim numarası

Sipariş kodu

F

71039436

Kit P.s.b. 40/8X 24V REx330 Ex

Çizim numarası

Sipariş kodu

F

71097759

Kit P.s.b. 8X 24V REx330 HE Ex

Çizim numarası

Sipariş kodu

F

71097761

Kit 10 fuses 250 VAC T800 MA

Çizim numarası

Sipariş kodu

7

50094002

Kit 10 fuses 250 VAC T 2A00

Çizim numarası

Sipariş kodu

7

50094003

Kit meas.amplifier Promass 83/8ME WEA EX

Çizim numarası

Sipariş kodu

B

50106097

Kit meas. amplifier 83 WEA HE EX

Çizim numarası

Sipariş kodu

B

71039409

Kit meas. amplifier PMASS 83 EES EX

Çizim numarası

Sipariş kodu

B

50106098

Kit meas. amplifier 83 EES HE EX

Çizim numarası

Sipariş kodu

B

71039410

Kit meas. amplifier PMASS 83 SEA EX

Çizim numarası

Sipariş kodu

B

50106099

Kit meas. amplifier 83 SEA HE EX

Çizim numarası

Sipariş kodu

B

71039411

Kit meas. amplifier Pmass 83 CN EX

Çizim numarası

Sipariş kodu

B

50108135

Kit meas. amplifier 83 CN HE EX

Çizim numarası

Sipariş kodu

B

71039412

Kit amp. 83, HART7, DE+FR+IT+ES+EN, EX

Çizim numarası

Sipariş kodu

B

71261695

Kit amp. 83,HART7, DE+FR+IT+ES+EN, HE,EX

Çizim numarası

Sipariş kodu

B

71261696

Kit amp. 83, HART7, RU+NL+PT+CS+EN, EX

Çizim numarası

Sipariş kodu

B

71261697

Kit amp. 83,HART7, RU+NL+PT+CS+EN, HE,EX

Çizim numarası

Sipariş kodu

B

71261698

Kit amp. 83, HART7, ZH+PL+ID+EN, EX

Çizim numarası

Sipariş kodu

B

71261699

Kit amp. 83, HART7, ZH+PL+ID+EN, HE, EX

Çizim numarası

Sipariş kodu

B

71261700

Kit amp. 83, HART7, JA+SV+NO+FI+EN

Çizim numarası

Sipariş kodu

B

71261701

Kit amp. 83,HART7, JA+SV+NO+FI+EN, HE

Çizim numarası

Sipariş kodu

B

71261702

Kit commodul current/freq./2Relay Ex

Çizim numarası

Sipariş kodu

C

50098300

Kit I/O current/frequency/2Relay HE EX

Çizim numarası

Sipariş kodu

C

71039475

Kit com 53/55/83/93 curr./freq. out Ex

Çizim numarası

Sipariş kodu

C

50098301

Kit I/O current/frequency out HE EX

Çizim numarası

Sipariş kodu

C

71039476

Kit commodul Iout passive/Frequency Exi

Çizim numarası

Sipariş kodu

C

50098302

Kit I/O Iout active/Frequency HE Exi

Çizim numarası

Sipariş kodu

C

71039478

Kit commodul Iout active/Frequency Exi

Çizim numarası

Sipariş kodu

C

50098303

Kit I/O Iout passive/Frequency HE Exi

Çizim numarası

Sipariş kodu

C

71039479

Çizim numarası

Sipariş kodu

C

71066579

Kit I/O 50/53/55/80/83 Profib. PA HE Ex

Çizim numarası

Sipariş kodu

C

71066580

Kit I/O Foundation Fieldbus C02 Ex

Çizim numarası

Sipariş kodu

C

50101264

Kit I/O Foundation Fieldbus C14 EX

Çizim numarası

Sipariş kodu

C

71095035

Kit I/O Foundation Fieldbus C02 Ex

Çizim numarası

Sipariş kodu

C

50101264

Kit I/O Foundation Fieldbus C14 EX

Çizim numarası

Sipariş kodu

C

71095035

Kit I/O Foundation Fieldbus HE C02 EX

Çizim numarası

Sipariş kodu

C

71039483

Kit I/O Foundation Fieldbus HE C14 EX

Çizim numarası

Sipariş kodu

C

71095037

Kit com 83/65 2x Iout aktiv Exi

Çizim numarası

Sipariş kodu

C

50104625

Kit I/O 83 2x Iout active HE Exi

Çizim numarası

Sipariş kodu

C

71039480

Kit com 83/65 2x Iout passiv Exi

Çizim numarası

Sipariş kodu

C

50104626

Kit I/O 83 2x Iout passive HE Exi

Çizim numarası

Sipariş kodu

C

71039481

Kit I/O 50/53/55/83/65/8ME Profib. DP Ex

Çizim numarası

Sipariş kodu

C

71021742

Kit I/O 50/53/55/83 Profibus DP HE EX

Çizim numarası

Sipariş kodu

C

71039484

Kit Com ModbusRS485+stat.In 2Interf.Ex

Çizim numarası

Sipariş kodu

D

71021743

Kit I/O Modb.RS485+Stat.In 2Interf.HE EX

Çizim numarası

Sipariş kodu

D

71039485

Kit I/O Profib. DP+Stat.In 2 Interf. Ex

Çizim numarası

Sipariş kodu

D

50108002

Kit I/O Profib.DP+Stat.In 2 Interf.HE EX

Çizim numarası

Sipariş kodu

D

71039486

Kit Commodul current out 3 Interface Ex

Çizim numarası

Sipariş kodu

D

50096833

Kit I/O current out 3 Interface HE EX

Çizim numarası

Sipariş kodu

D

71039477

Kit I/O Modul 53/83 Ethernet

Çizim numarası

Sipariş kodu

D

71105712

Çizim numarası

Sipariş kodu

2

50096834

Çizim numarası

Sipariş kodu

2

50096834

Kit Sub PCB current out HE

Çizim numarası

Sipariş kodu

2

71039487

Kit Sub PCB current out HE

Çizim numarası

Sipariş kodu

2

71039487

Kit Sub PCB frequency out

Çizim numarası

Sipariş kodu

3

50096835

Kit Sub PCB frequency out

Çizim numarası

Sipariş kodu

3

50096835

Kit Sub PCB frequency out HE

Çizim numarası

Sipariş kodu

3

71039489

Kit Sub PCB frequency out HE

Çizim numarası

Sipariş kodu

3

71039489

Çizim numarası

Sipariş kodu

4

50096837

Kit Sub PCB Status input HE

Çizim numarası

Sipariş kodu

4

71039492

Çizim numarası

Sipariş kodu

5

50096836

Çizim numarası

Sipariş kodu

5

50096836

Çizim numarası

Sipariş kodu

5

71039491

Çizim numarası

Sipariş kodu

5

71039491

Çizim numarası

Sipariş kodu

6

50098562

Kit Sub PCB current input HE

Çizim numarası

Sipariş kodu

6

71039488

Kit Sub PCB 53/83 Ethernet

Çizim numarası

Sipariş kodu

37

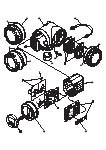

71105711

Çizim numarası

Sipariş kodu

E

50096754

Kit display modul Wall enclosure

Çizim numarası

Sipariş kodu

J

50096755

Kit Bus/connec.b.5X/40/8X/65 field hous.

Çizim numarası

Sipariş kodu

G

50094016

Kit Bus/connec. board 53/83 Ethernet

Çizim numarası

Sipariş kodu

G

71105709

Kit Bus PCB/PCB carr.5X/8X/9X/65 wall

Çizim numarası

Sipariş kodu

21

50094017

Kit Bus/connec.b.5X/8X SS-housing

Çizim numarası

Sipariş kodu

H

50099099

Kit connec. board PMASS8X wall enclo

Çizim numarası

Sipariş kodu

19

50098637

Kit connec. board 8X wall enclosur HE

Çizim numarası

Sipariş kodu

19

71039493

Kit connec. board In/Output Wall encl

Çizim numarası

Sipariş kodu

18

50094014

Kit connection board 8X FS

Çizim numarası

Sipariş kodu

A

50098705

Kit connection board 8X FS HE

Çizim numarası

Sipariş kodu

A

71039494

Kit connection board 8X FS Ex

Çizim numarası

Sipariş kodu

A

50098706

Kit connection board 8X FS HE EX

Çizim numarası

Sipariş kodu

A

71039495

Kit Termin.Block field hous. 5X/8X/40/65

Çizim numarası

Sipariş kodu

29

50108139

Kit Termin.Block Wall encl. 5X/8X/9X/65

Çizim numarası

Sipariş kodu

30

50108140

Kit T-DAT Transmitter Data Chip

Çizim numarası

Sipariş kodu

1

50094004

Kit S-Dat Promass 83/8ME programmed

Çizim numarası

Sipariş kodu

S

71003952

Kit Cover 5X/8X with window SS-housing

Çizim numarası

Sipariş kodu

17

50099100

Kit Cover 5X/40/8X/65 with window

Çizim numarası

Sipariş kodu

8

50094026

Kit Cover 5X/40/8X/93/65 with window Exd

Çizim numarası

Sipariş kodu

32

50094027

Kit Cover 5X/40/8X/65 version blind

Çizim numarası

Sipariş kodu

9

50094028

Kit Cover 5X/40/8X/93/65 vers. blind Exd

Çizim numarası

Sipariş kodu

33

50094029

Kit Cover Connection terminal

Çizim numarası

Sipariş kodu

10

50094038

Kit Cover Connection terminal

Çizim numarası

Sipariş kodu

10

50094038

Kit Cover 5X/40/8X/93/65 Conn.termi.Exe

Çizim numarası

Sipariş kodu

34

50094039

Kit Cover 5X/40/8X/93/65 Conn.termi.Exd

Çizim numarası

Sipariş kodu

35

50094040

Kit 10 cable glands M20x1,5

Çizim numarası

Sipariş kodu

15

50096840

Kit 10 cable glands M20x1.5 Ex

Çizim numarası

Sipariş kodu

15

50098036

Kit 10 cable glands M20x1.5 Ex

Çizim numarası

Sipariş kodu

15

50098036

Kit 10 cable glands M20x1.5 Ex

Çizim numarası

Sipariş kodu

15

50098036

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Çizim numarası

Sipariş kodu

15

50098041

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Çizim numarası

Sipariş kodu

15

50098041

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Çizim numarası

Sipariş kodu

15

50098042

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Çizim numarası

Sipariş kodu

15

50098042

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Çizim numarası

Sipariş kodu

15

50098042

Kit Cable gland Profibus PA

Çizim numarası

Sipariş kodu

15

50098037

Kit Cable gland Found. Fieldbus

Çizim numarası

Sipariş kodu

15

50094984

Kit 1 Bus connector 53/83 Ethernet

Çizim numarası

Sipariş kodu

15

71105713

Kit 1 Bus connector 53/83 Ethernet

Çizim numarası

Sipariş kodu

15

71105713

Kit Circuit board cpl field/SS-housing

Çizim numarası

Sipariş kodu

12

50096839

Kit Bushing to field/SS-housing

Çizim numarası

Sipariş kodu

14

50099102

Kit Terminal protective Cover Ex

Çizim numarası

Sipariş kodu

36

71008445

Kit Ground terminal / Cover clamp

Çizim numarası

Sipariş kodu

13

50096841

Kit 2 Screening sheet field housing

Kit 2 Screening sheet wall enclo.

Kit housing gaskets SS-Field housing

Çizim numarası

Sipariş kodu

16

50099101

Kit Seal cover to Wall enclosure

Çizim numarası

Sipariş kodu

20

50094041

Kit 10 Seal cover to field housing

Çizim numarası

Sipariş kodu

11

50094050

Kit Part 8X Stainless housing comp.

Çizim numarası

Sipariş kodu

23

50098701

Kit Part 8X fieldhousing compact

Çizim numarası

Sipariş kodu

22

50098702

Çizim numarası

Sipariş kodu

24

50098704

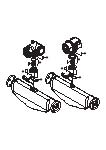

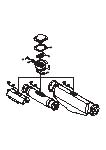

Kit cable Promass remote version 10m

Çizim numarası

Sipariş kodu

28

50093554

Kit cable Promass remote version 20m

Çizim numarası

Sipariş kodu

28

50093573

Kit cable PROMASS remote version 10m Ex

Çizim numarası

Sipariş kodu

28

50098567

Kit cable PROMASS remote version 20m Ex

Çizim numarası

Sipariş kodu

28

50098568

Promass 83, software package

Transmitter 80/83/84, mounting set

Gizliliğinize değer veriyoruz

Tarayıcı deneyiminizi iyileştirmek, site işlevselliğini optimize etmek adına istatistikleri toplamak ve size uygun reklam ve içerikler göstermek için çerezleri kullanıyoruz.

"Tümünü kabul et" seçeneği ile çerez kullanımımıza rıza göstermiş olursunuz. Çerez Politikamız .

Özelleştir

Sadece gerekli olanı kabul et

Tümünü kabul et