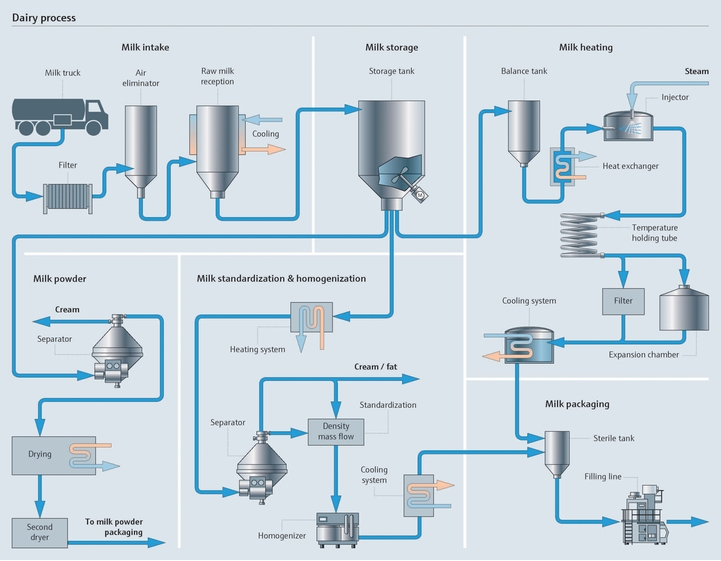

Dairy production is a business with tight margins and high quality requirements. Milk processing can be optimized to control costs while maintaining product quality at a consistently high level. Thermal milk processing, in particular, is of paramount importance to consumer safety and plant efficiency. Accurate, innovative measurement technology sensors ensure thermal processing in the correct temperature range and compliance with strict rules.

Önemli gerçekler

4000 € / yıl

enerji kayıpları

ve çok daha fazla enerji kaybı bir UHT ünitesinin sıcaklık ölçümündeki sapma sebebiyle yaşandı. Zaten ayar noktasının sadece iki derece üzerindeki bir sıcaklık, gereksiz yere kullanılan enerji için yüksek ek maliyetlere yol açabilir. Hassas ölçüm teknolojisi ile kaynaklarınızı kontrol altında tutun.

What you can do

Click through these maps and learn in detail how you can optimize your dairy production!

Fast temperature sensors improve heating control

The critical control point for successful pasteurization control is temperature. Accuracy and response time ensure that no energy is wasted and the product is not exposed to more thermal stress than necessary.

Our expertise in the field

Endress+Hauser has invented the fastest temperature sensor for hygienic processes. This innovative technology helps you to improve quality and reduce cost. Furthermore, the combination of precise, fast and stable temperature measurement delivers the highest degree of process quality and reliable product quality.

- Install our innovative temperature sensor iTHERM TM411 to improve your temperature monitoring in UHT processing.

- Benefit from the shortest response times (t90 = 0.75 s) in the market thanks to iTHERM QuickSens technology.

- Take advantage from significant time savings during recalibration (up to 20 minutes per measuring point) with iTHERM QuickNeck.

- Reduce risk and improve process safety in critical applications with the help of our self-calibrating temperature sensor iTHERM TrustSens.

Flow measurement in milk pasteurization

Accurate flowmeters ensure the right amount of heat is applied to achieve safe results.

Our expertise in the field

Electromagnetic flowmeters carry the main burden of flow measurement in dairy operations and play a critical role in milk heating.

- Benefit from integrated temperature and conductivity measurement of Proline Promag H.

- Heartbeat Technology combines diagnostic, verification and monitoring functions for process optimizations.

Reliable level sensors

One of the more challenging applications in thermal processing systems is the level control of the balance tank. The small tank sees rapid level and temperature changes.

Our expertise in the field

Hydrostatic level sensor are ideal for this application. Temperature compensated and with ranges down to 100mm H2O, they set the standard for reliability.

- Use Deltapilot FMB50 with remote electronics. It also help you to reduce risk in the often harsh environment and cleaning cycles.

- Alternatively, the compact point level switch Liquiphant FTL33 for hygienic applications can be used.

Differential pressure measurement across heat exchanger

To ensure food safety, the differential pressure across the regeneration stage must be maintained. Stability and trust in measurement is key.

Our expertise in the field

For this critical application, an electronic differential pressure measurement is recommended.

- Optimize your measurement using our innovative electronic dp Deltabar FMD72.

Buildup monitoring to optimize product quality

The microbiological stability of dairy products is crucial for their shelf life and quality, which is often regulated by law. However, heating milk also leads to contamination on the inner walls. This contamination affects the efficiency of the heating cycle and is a potential cause of product contamination. Therefore, controlling the fouling behavior throughout the heating process and the presence of product in the holding tube is key to process control and optimization of product quality.

Our expertise in the field

Our compact point level devices Liquiphant FTL43 and Liquipoint FTW33 can detect process anomalies such as fouling or build-up. Installed in the holding tube of the pasteurization process, it can continuously monitor the formation and degree of buildup. This helps to decide if a cleaning process is necessary or if the production time can still be extended without affecting the product quality.

Keep your measurement up-to-date

Regular maintenance and calibration ensures that the measuring instruments controlling critical processes remain in spec, which is essential to safeguard food safety and quality.

Our expertise in the field

From on-site to fully accredited laboratory calibration, Endress+Hauser provides timely, traceable, and cost-effective maintenance services to ensure both high plant availability and compliance of your instruments. Our calibration experts will support you in optimizing all activities across your installed base.

- Keep the quality of your instruments up-to-date with minimal process interruption thanks to our maintenance services.

Benefits

Apart from our industry expertise and broad product portfolio, we want to support our customers with valuable process knowledge. We will help ensure that all local and international requirements are met. The promise to be a reliable partner is our goal. We strongly believe in long-lasting relationships with our customers, not just the short range profit.

Önemli gerçekler

0.75 seconds

response time (t90)

iTHERM QuickSens offers the fastest response times in the market for optimum process control.

Önemli gerçekler

3 million

Proline Promag

electromagnetic flowmeters sold since launch in 1977 in a wide range of applications.

Önemli gerçekler

8,700

patents and patent applications

protect the intellectual property behind Endress+Hauser’s products, solutions and services.

Our offering

Endress+Hauser understands the high demands and challenges in dairy processing. We offer a complete portfolio of hygienic flow, level, temperature, pressure and analytical sensors designed, manufactured and optimized for the food and beverage industry. Our common goal: ensure product safety and customer health.

- Precise, robust and reliable measurement technology optimized for industry requirements.

- Easy to clean and absolutely tight sensors. Ingress protection class up to IP69K available to withstands high pressure and steam cleaning.

- Hygienic sensors meet 3-A sanitary standards and are certified according to test procedure of EHEDG.

- Food contact material compliant to FDA "GRAS", EC 1935/2004 and China GB4806.

- Seamless integration into any control system.

.jpg)